"Cooked cereals" - what nutritionist and feedmiller should knowDr. Heinrich Kleine Klausing

"Cooked cereals" is surely not a completely new topic for the feedmilling industry. Especially in the 80's some experts reported in the literature about this. However the questions "For which and why should grain starch be broken down?", "How can the breakdown of starch be done?" and "Which breakdown degree can be achieved?" are discussed again increasingly inside the feedmilling industry. With this article answers are given on these questions and new technical developments are presented.

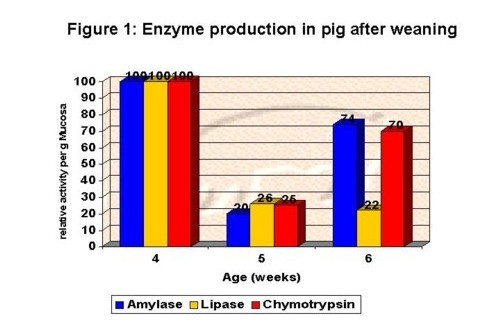

The most important area where "cooked cereals" are used, is the nutrition of young animals, especially the feeding of weaned piglets. Weaning represents a drastic change for the piglets. Under nutritional physiology aspects this is characterised by a shift from a diet of high digestible protein, fat and lactose originating from the sow milk to nutrients of plant origin. During this weaning phase the activity of various digestive enzymes changes, in particular the activity of amylase, which is important for starch digestion. Figure 1 shows an overview of the results of a study by Makking dating back to 1993. By comparison with weaning time, the amylase, chymotrypsin and lipase activity dropped to just a quarter to a fifth. In the second week after weaning the concentration of lipase was still low, and the chymotrypsin and amylase activity rose to 70 and 74 per cent respectively of activity at the time of weaning, respectively. This situation must be taken into account when making up piglet diet and selecting raw materials.

In this phase grain is, as ever, the most important source of energy. For many years now it has been successful practice to "break down" the starch in a part of the grain used in the feed so that most of it can be digested enzymatically in the small intestine with distinctly limited amylase activity. In addition to a "performance effect" in the form of improved digestibility and increased feed intake connected with the breakdown of starch, it is especially important to avoid excessive flooding of the large intestine with undigested starch. This eliminates a major viability basis for potential harmful germs such as E.coli und thus prevents diarrhoea. Such effects are more important than ever today, since on the one hand feed additives with an antibiotic effect are no longer available or are no longer accepted by society. On the other hand the application of intestine-stabilising medicaments by the responsible veterinarian is also strongly regulated. Every feeding measure that makes a contribution to keeping the gastro-intestinal tract naturally healthy should therefore be specifically reviewed and used.

Starch breakdown technologies

The process heat enters the product in one or more of the following ways:

The "opticon®" process technology developed by our company is a major further development of known extrusion technology. Figure 2 provides a look of the engineering. This achieves targeted intensive material conversion like the "moist" extrusion process described above. Thanks to the plant concept in accordance with the invention, however, no energy-costly drying of the treated material is necessary. Only a conventional cooler follows the treatment process.

This newly-developed technology is applied to improve the nutritional value of various components for productive livestock and pets. One of its features is to largely break down the starch in various grain species as mentioned above. A further practical area of application is the clear reduction of the protein degradability in a mixture of soyabean and rape-seed meal in the rumen of dairy cows ("rumen-protected protein"). The opticon® process technology is also used to inactivate the urease in raw soya beans and is thus a complete high-grade substitute for the toasting process that has been customary to date.

Starch and "starch breakdown degree"

Grain contains between 40 and 60 per cent starch depending on the cereal species. In purely chemical terms starch can be broken into amylase and amylopectin. The amylase, accounting for about 20 to 30 per cent of grain starch, consists of 1,4-α-glycosidically bonded glucose molecules, that in this bonding represent long helical chains. Amylopectin with about 70 to 80 per cent of the starch is a branched polysaccharide in which between 2.000 and 200.000 glucose molecules are bonded 1,4- and 1,6-α-glycosidically. The 1,6 bonding generates side chains and hence the complex branching of the molecule. The ratio of amylose to amylopectin, the chain length and the degree of branching of the glucose chains have a clear influence on the technical properties of the various grain species and their starch digestibility.

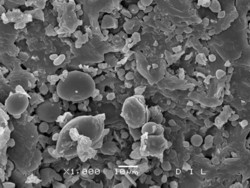

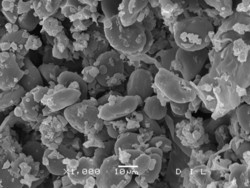

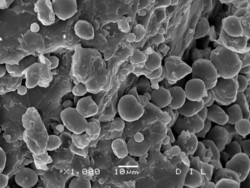

Starch is present in the floury portion of grain corn in the form of individual granula with a size between 2 and 200 µm. These starch granula can be seen clearly under the scanning electron microscope (1000-fold magnification). Figure 3a shows a photo of untreated wheat, Figure 4a shows untreated barley and Figure 5a shows untreated maize. The starch granula are held together very stably in their interior by hydrogen bridges. The branched molecule chains of the amylopectin can form semi-crystalline to crystalline areas in these granula together with the un-branched amylase molecules. This firmly organised structure is water-insoluble and in its native, non-crushed form highly resistant to enzymatic degradation.

By intensive mechano-hydrothermal treatment of grain (customary milling and subsequent extrusion using the opticon® technology) these structures are modified right down into the molecular range. The starch is "broken down" and improved starch digestibility is achieved in young piglets with distinctly limited amylase activity in the small intestine. The main effects occur as a result of clear enlargement of the surface and far-reaching disintegration of the semi-crystalline and crystalline areas and of the amylopectin and the amylase. These structural changes are clearly visible under the scanning electron microscope, as shown in Figures 3b, 4b and 5b. The typical starch granula are largely destroyed by the treatment and chiefly melted together to form flat areas like melted plastic.

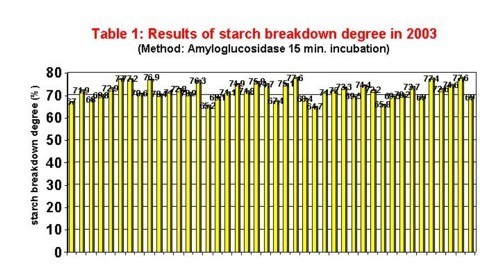

It is common knowledge that the degree of starch modification is influenced substantially by the process technology used and the physical parameters effective here. This modification can also be determined analytically as "starch breakdown degree" with the "Amyloglucosidase Method" (AMG-Method) (Agricultural Testing and Research Institute Nord-West, LUFA Nord-West, 2003). In this method the material to be examined is mixed with the enzyme amyloglucosidase after various preparatory steps have been taken. This enzyme splits off glucose on starch molecules solely at the end of the chain. The glucose split off is measured after an incubation period of 15 minutes. The content of hydrolysed starch is calculated from this and set in relation to the crude starch content.

Why is the enzyme amyloglucosidase used in this method, and not the α-amylase present in the piglet's digestive tract too? By comparison with amyloglucosidase, the α-amylase attacks starch molecule chain and molecule fragments. Jansen (1989) states in this connection that such fragments also occur as a result of the technical treatment of the starch and therefore a detection process using amylase or a mixture of α-amylase and amyloglucosidase would not be suitable. Treatment and enzyme effects would be superimposed on each other and the useful information provided by the result would therefore be very limited. That is why the AMG method has been considered for many years as the suitable method for determining the degree of starch breakdown.

The duration of incubation with the enzyme amyloglucosidase and the temperature conditions under which incubation occurs are crucial for the values determined and for comparability of the degrees of breakdown in different grain treatment methods. Using the method described here the starch breakdown degree is determined in standard fashion with an incubation period of 15 minutes at a temperature of 50°C. These parameters are always stated with the results. Furthermore, to interpret the results it is important to know that according to the information supplied by the Agricultural Testing and Research Institute (LUFA Nord-West (2003)) the values determined can only be compared directly with one another within the same grain species.

Influence of the treatment

In addition to wheat, the process technology can also be used to break down barley and maize mechano-hydrothermally. Appropiate studies have also resulted in a starch breakdown degree* of over 70 per cent on average for opticon®-treated barley too. However, it is more difficult to modify the starch in maize than in wheat and barley. This is attributable to a change in the order condition of starch during drying of maize observed by Münzing (2003a). Due to the much higher moisture content on harvesting by comparison with wheat and barley, maize must always be dried intensively. According to Münzing (2003b) individual molecule chains associate during such intensive thermal treatment, either by amorphous areas of the starch gradually transferring to a thermodynamically more stable condition, or by the starch crystallite being perfected by further aggregation of the compacted sequences. Grain specialists describe this change as a "tempering or annealing effect". This makes the starch less prone to thermal, hydrothermal, mechanical and pressure-mechanical, as well as enzymatic and microbial attacks. This is also the reason why native maize starch is more poorly digestible for young monogastrics than, for instance, wheat starch or shows higher rumen stability among ruminants. Results of the average starch breakdown degree* of opticon®-treated maize (opticorn®, Figure 7) of 65 per cent are further evidence of this connection.

Summary

In addition to the known mechano-hydrothermal techniques for "breaking down starch" in grain, the opticon® technology presented here provides a new process that represents a major further development of known extrusion technology. A high degree of substance modification is achieved in the treated products without the finished product having to be subsequently dried. The starch breakdown degree* achieved in wheat and barley of on average over 70 per cent and the average of 65 per cent for maize document the effectiveness of the process.

* average starch breakdown degree (AMG-Method): Incubation 15 minutes at 50°C Literature

LUFA Nord-West (2003): personal report Dr. Egert 28 August 2003

MAKKINK, C.A. (1993): Of pigs, dietary proteins, and pancreatic proteases

MÜNZING, K. (2003a): personal report Dr. Münzing 29 August 2003

MÜNZING, K. (2003b): Aktuelle Probleme bei der Qualitätssicherung der Weizenernte 2003

Oktober 2003

|